Flashing tapes: the keys to reliability

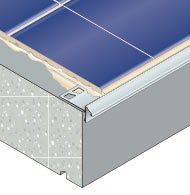

The flashing strips play a decisive role in the separation of the runoff water and the protection of the heads of the sealing rings.

Drainage gaps, protection of the heads of the sealing rings: the flashing strips play a decisive role. A FFB / AQC study (French Building Federation and Construction Quality Agency) made it possible to specify criteria for the choice of materials and the most important points for an implementation ensuring the sustainability of the structures equipped.

A survey conducted in 2003 reported that a significant number of survey disorders were caused by flashing strip failures. Since then, the provisions applicable to surveys have been greatly strengthened with the revision of DTU 43.1.

The key role played by two key elements in the reliability of these structures:

-

The Caulking :

The process is well known. Poor implementation or the use of unsuitable products can lead to a risk of separation and cracking of the caulking product, with the consequent risk of water infiltration. Two years of tests allowed to appreciate the behavior of a dozen mastics subjected to severe mechanical and thermal stresses. At the end of these tests, whether they are made of silicone or polyurethane, it is not the chemical nature of the products that is involved but simply their performance.

Their behavior will be satisfactory, subject of course to correct implementation. -

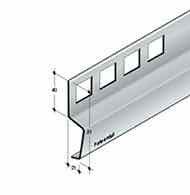

The geometry of the upper groove:

The square shape is the most favorable to absorb the dimensional variations because it limits the constraints at the levels of the bonding planes.

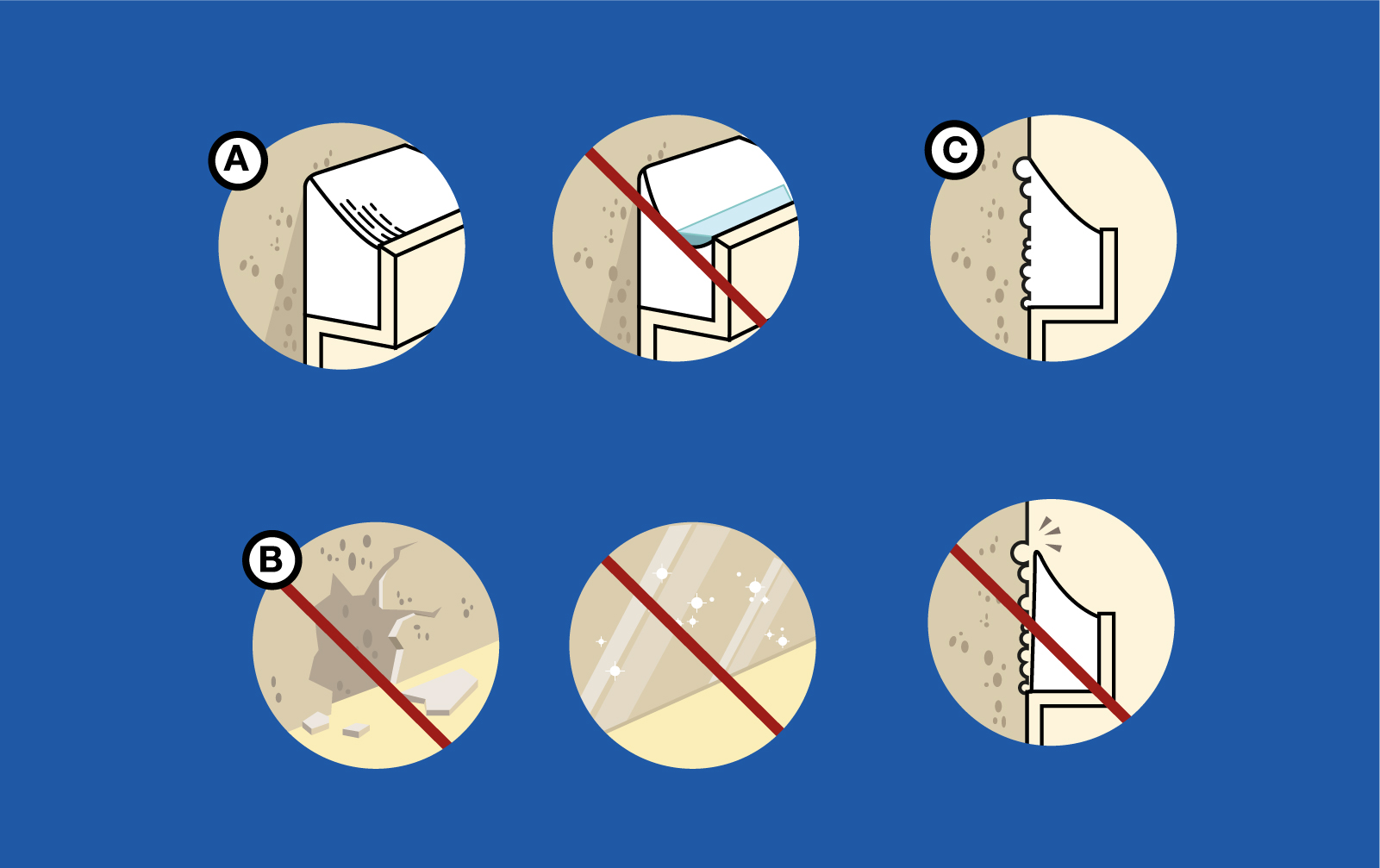

Finally, on the ground, taking into account these two elements should ensure the performance of the flashing strips, provided that they respect at least three prerequisites:

- First, the gap between each screw, which should not exceed 30 cm.

- Then, the surface condition of the concrete. The latter must be healthy and cohesive.

- The use of accessories (junction boxes, corner sleeves) which guarantee the protection to the right of the expansion sets and the use of aluminum protector at the head for the terraces accessible to the public.

To conclude, as with all waterproofing structures, the flashing strips must be checked at least once a year. Consider maintaining them regularly.

More information about our product Solinet 15/40, for inaccessible terrace and private access

.

The technical opinion of the Solinet range is available here: http://www.cstb.fr/pdf/atec/GS05-F/AF162497.pdf

Source : Etanchéité INFO (Mars 2007 – Mise à jour 2011)

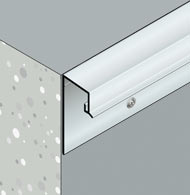

Aluminium flashing system for flat roof tops

Aluminium flashing system for flat roof tops Roof edging and parapet wall raising piece system

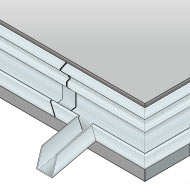

Roof edging and parapet wall raising piece system Aluminium parapet extension and facade band system

Aluminium parapet extension and facade band system Aluminum coping systems

Aluminum coping systems Rainwater collector and drainage system

Rainwater collector and drainage system Gravel protection strips and boxes

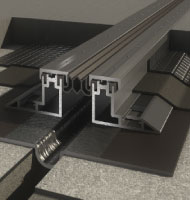

Gravel protection strips and boxes Mechanical protection system for expansion joints

Mechanical protection system for expansion joints Supporting structure for mechanical equipment on roofs

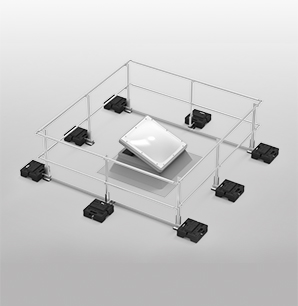

Supporting structure for mechanical equipment on roofs Système de structure support en toiture terrasse

Système de structure support en toiture terrasse Freestanding machine dressing system on roofs

Freestanding machine dressing system on roofs Aluminium safety guardrail for flat roofs without public access

Aluminium safety guardrail for flat roofs without public access Aluminium guardrail for flat roofs without public access

Aluminium guardrail for flat roofs without public access Aluminium height-adjustable saftey guardrail for flat roofs without public access

Aluminium height-adjustable saftey guardrail for flat roofs without public access Échelles à crinoline et sauts de loup

Échelles à crinoline et sauts de loup Safe walk way and emergency escape way

Safe walk way and emergency escape way Roof lights safety railing system

Roof lights safety railing system Freestanding demarcation system on roofs

Freestanding demarcation system on roofs Guardrail with decorative filling

Guardrail with decorative filling Garde-corps à remplissage décoratif filant

Garde-corps à remplissage décoratif filant Steel design guardrail

Steel design guardrail Handrail on squire

Handrail on squire Separator for balconies and roof-tops

Separator for balconies and roof-tops Aluminium weather drips for external walls and balcony edges

Aluminium weather drips for external walls and balcony edges Gutter and drainage of balconies

Gutter and drainage of balconies Adjustable cladding system to protect balcony edges

Adjustable cladding system to protect balcony edges Customized cladding system to protect slab edges

Customized cladding system to protect slab edges Tiling weather drips and protection of balcony edges

Tiling weather drips and protection of balcony edges Finishing profiles for liquid waterproofing systems

Finishing profiles for liquid waterproofing systems Facade sealing system

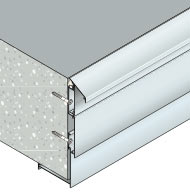

Facade sealing system Adjustable profiles for the insulation of facades

Adjustable profiles for the insulation of facades Flashing system for coated facades

Flashing system for coated facades Grab bar system

Grab bar system Window support system

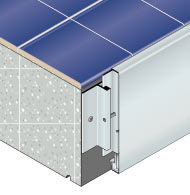

Window support system Window support system for insulated facades

Window support system for insulated facades Système d'appui de fenêtre pour construction à ossature ou bardage bois

Système d'appui de fenêtre pour construction à ossature ou bardage bois Accessibility solutions for those with reduced mobility

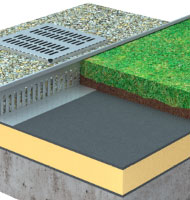

Accessibility solutions for those with reduced mobility Drainage system for surface water

Drainage system for surface water